Preparation of Gelatine Solutions

Gelatine is a protein product derived from collagen. It is a colourless, tasteless and odourless gelling agent used in many applications.

In the food industry, it is used in confectionery products such as jelly sweets, meat products and dairy and desserts. It can be used in low-fat products to replace texture and mouthfeel that is lost with removal of the fat. In beverages, gelatine can be used as a clarifying agent in beers and wines and can also be added to smoothies to enhance the texture.

It is also widely used in other industries for example in pharmaceutical tablets and capsules, nutraceuticals (food supplements), cosmetics such as face masks, and many types of industrial films, coatings and adhesives.

The Process

There are many types of Gelatine available, but a typical dispersion process would be as follows:

- Gelatine is normally supplied in powder or granule form, although sheets or “leaves” are also available and typically used in small scale kitchens and bakeries.

- Gelatine is partially soluble in cold water and will begin to swell and hydrate once wetted out. With a conventional agitator, the powder needs to be sprinkled carefully onto the surface of the liquid to avoid formation of agglomerates.

- The gelatine may be premixed with other powdered ingredients such as sugars, this acts as a dispersion aid to reduce the formation of agglomerates by separating the particles.

- The solution needs to be stirred for a while to allow it to hydrate and break up any lumps before being heated to complete solubilisation.

- The solubilisation temperature depends on the type and grade of the gelatine but it is typically around 35 – 45°C (95 – 105°F).

The Problem

Dispersion of gelatine using conventional agitators can give rise to several problems:

- Rehydrating gelatine can be slow and difficult to process, especially at higher concentrations due to its tendency to form lumps when added to water. This can be exacerbated by operator error.

- Agitators do not produce sufficient shear to rapidly break agglomerates down, leading to long mixing times and low yield. Many formulations contain unnecessarily high levels of gelatine to compensate for this, increasing raw material costs.

- Once viscosity increase has started, agitation of the solution and therefore powder dispersion becomes increasingly difficult.

- Long mixing times may be required to complete dispersion/hydration.

- Cold soluble gelatine when not properly dispersed will gradually hydrate during storage or subsequent processing, leading to undesired changes in product viscosity.

The Solution

A Silverson high shear mixer can dramatically speed up this process, operation is as follows:

Stage 1

The vessel is charged with the base liquid and the mixer is started. The gelatine can be added straight into the vessel.

Stage 2

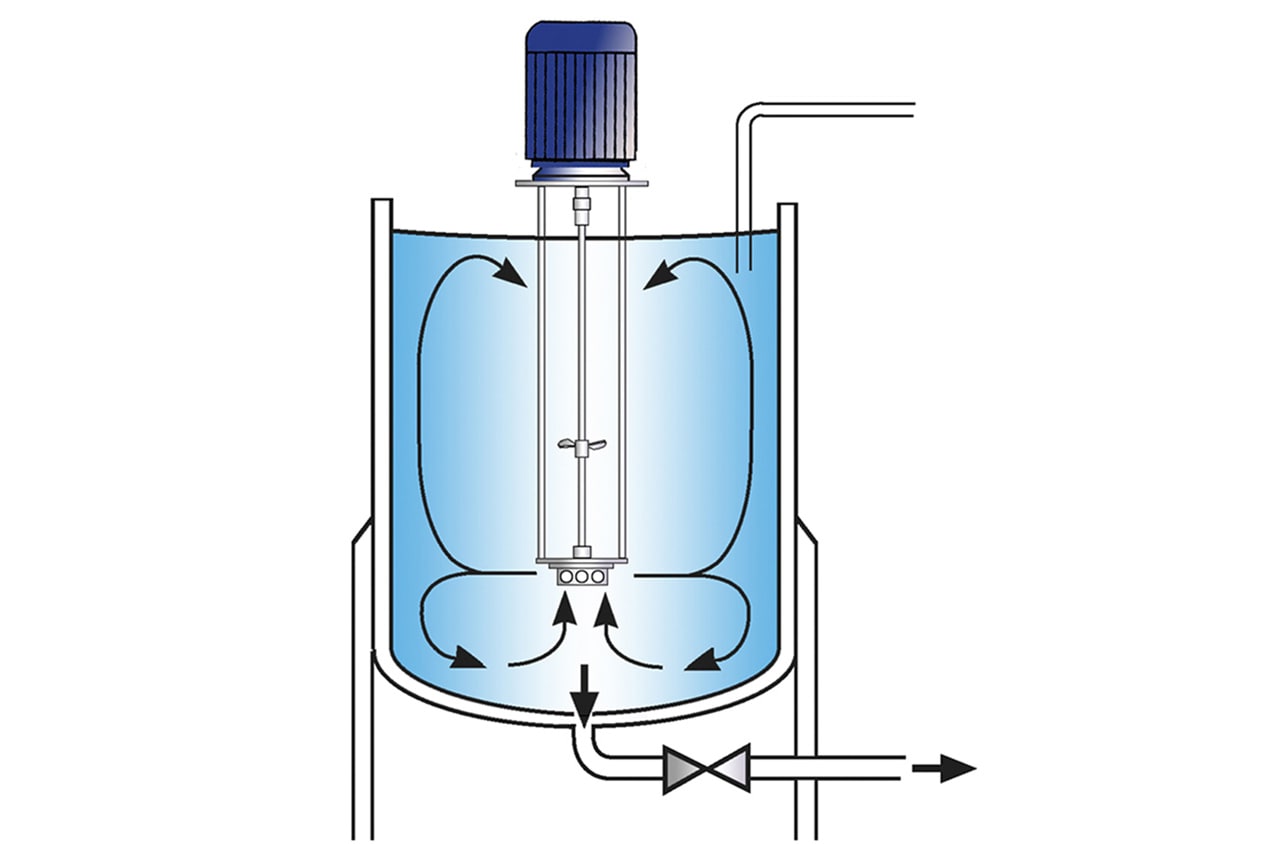

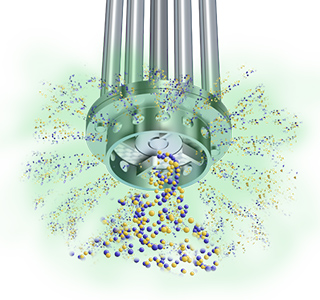

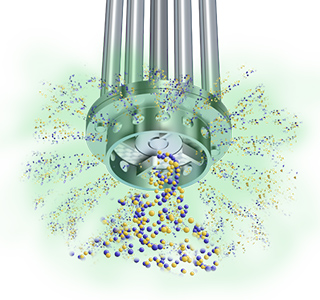

The high-speed rotation of the rotor creates a powerful suction that draws the powder and liquid upwards into the workhead where it is intensively mixed in the gap between the rotor and stator.

Stage 3

The mixture is then forced out through the holes in the stator and projected back into the body of the mix. This sets up a circulatory pattern of mixing in the vessel which ensures the powder is fully dispersed and hydrated.

-

Stage 1

Stage 1

The vessel is charged with the base liquid and the mixer is started. The gelatine can be added straight into the vessel.

-

Stage 2

Stage 2

The high-speed rotation of the rotor creates a powerful suction that draws the powder and liquid upwards into the workhead where it is intensively mixed in the gap between the rotor and stator.

-

Stage 3

Stage 3

The mixture is then forced out through the holes in the stator and projected back into the body of the mix. This sets up a circulatory pattern of mixing in the vessel which ensures the powder is fully dispersed and hydrated.

The Advantages

Silverson mixers offer a number of advantages for this application:

- Agglomerate-free mix.

- Gelatine can be added straight into the vessel, eliminating operator error.

- Maximised yield/functionality allows products to be formulated with reduced gelatine content, cutting raw material costs.

- Consistent product quality and repeatability.

- Rapid mixing times.

- Stable viscosity of end product.

The type of product, batch size and viscosity of the end product determine which mixer from the Silverson product line is most suitable:

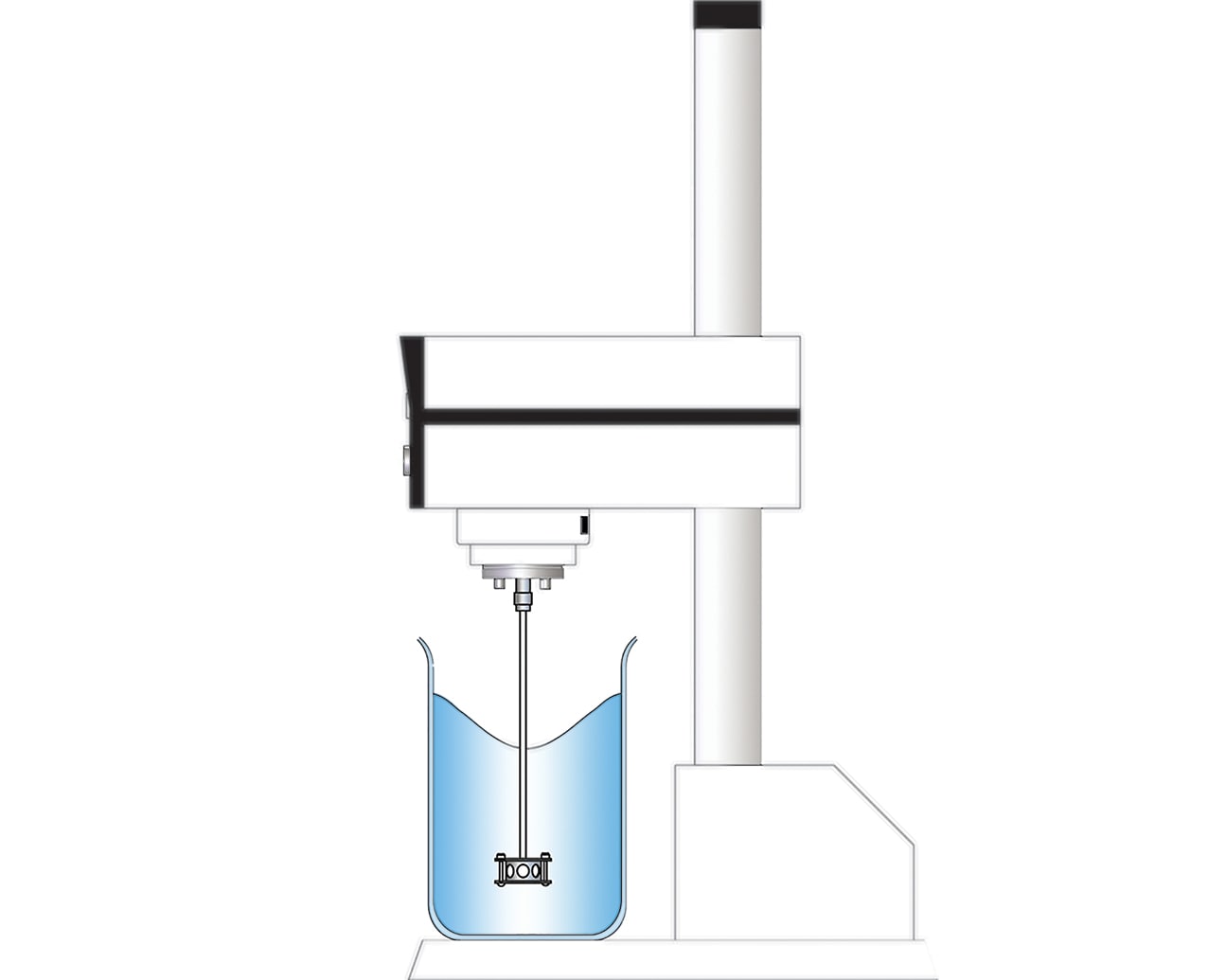

Laboratory Mixers

- Ideal for smaller batches and R&D work

- Suitable for batch sizes of up to 12 litres

- Built to the same tolerances as production models, providing easy and accurate means of scaling up

- Interchangeable workheads allow the unit to be adapted for a range of laboratory applications

Silverson Pilot Scale Mixers

- Features generally as Laboratory mixer above

- Suitable for batches of up to 50 litres, depending on viscosity

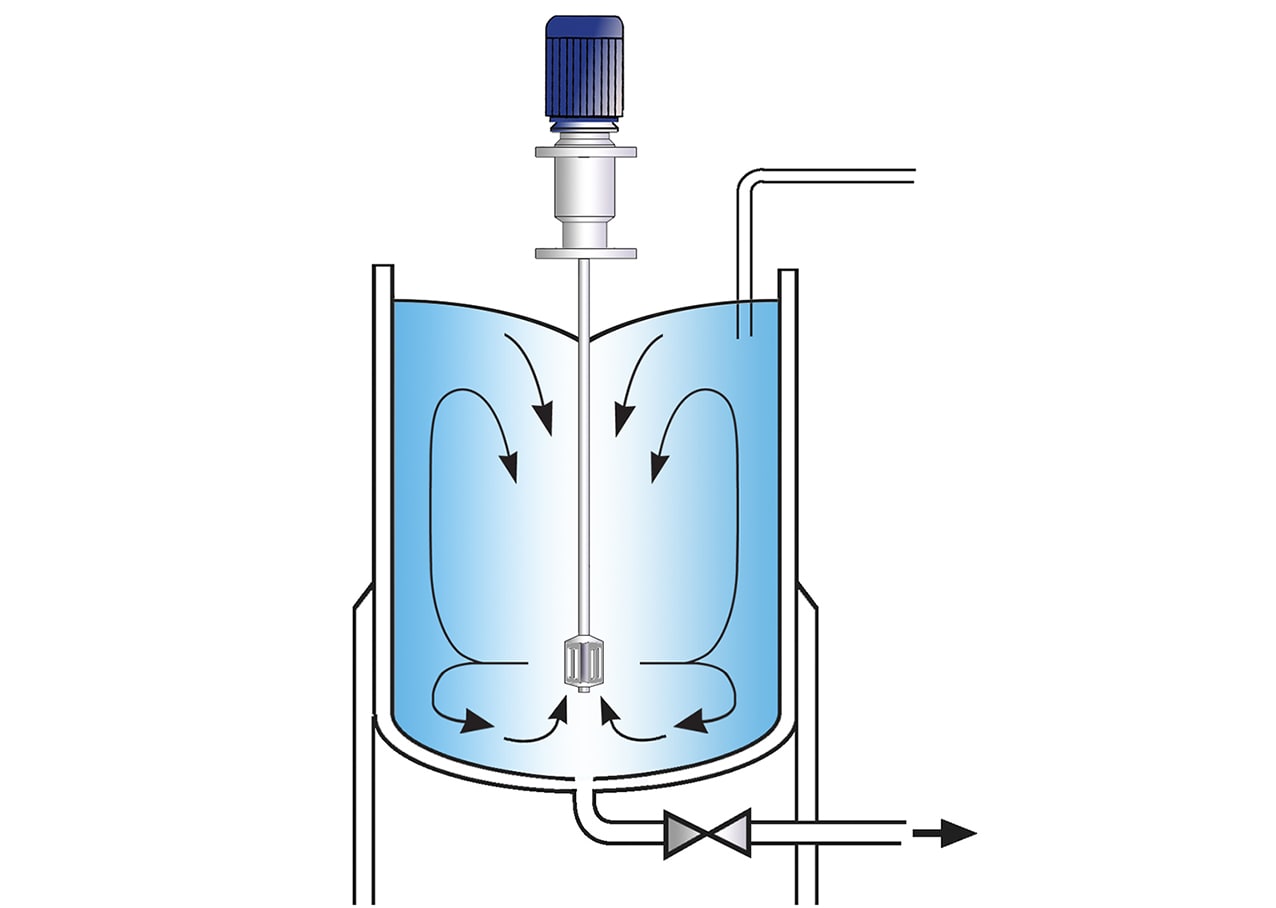

High Shear Batch Mixers

- Suitable for batches of up to 1000 litres

- Can be used on mobile floor stands

- Can easily be moved from vessel to vessel

Silverson Ultramix

- Excellent in-tank movement

- Capable of rapidly incorporating large volumes of powders

- Ideal for higher viscosity mixes

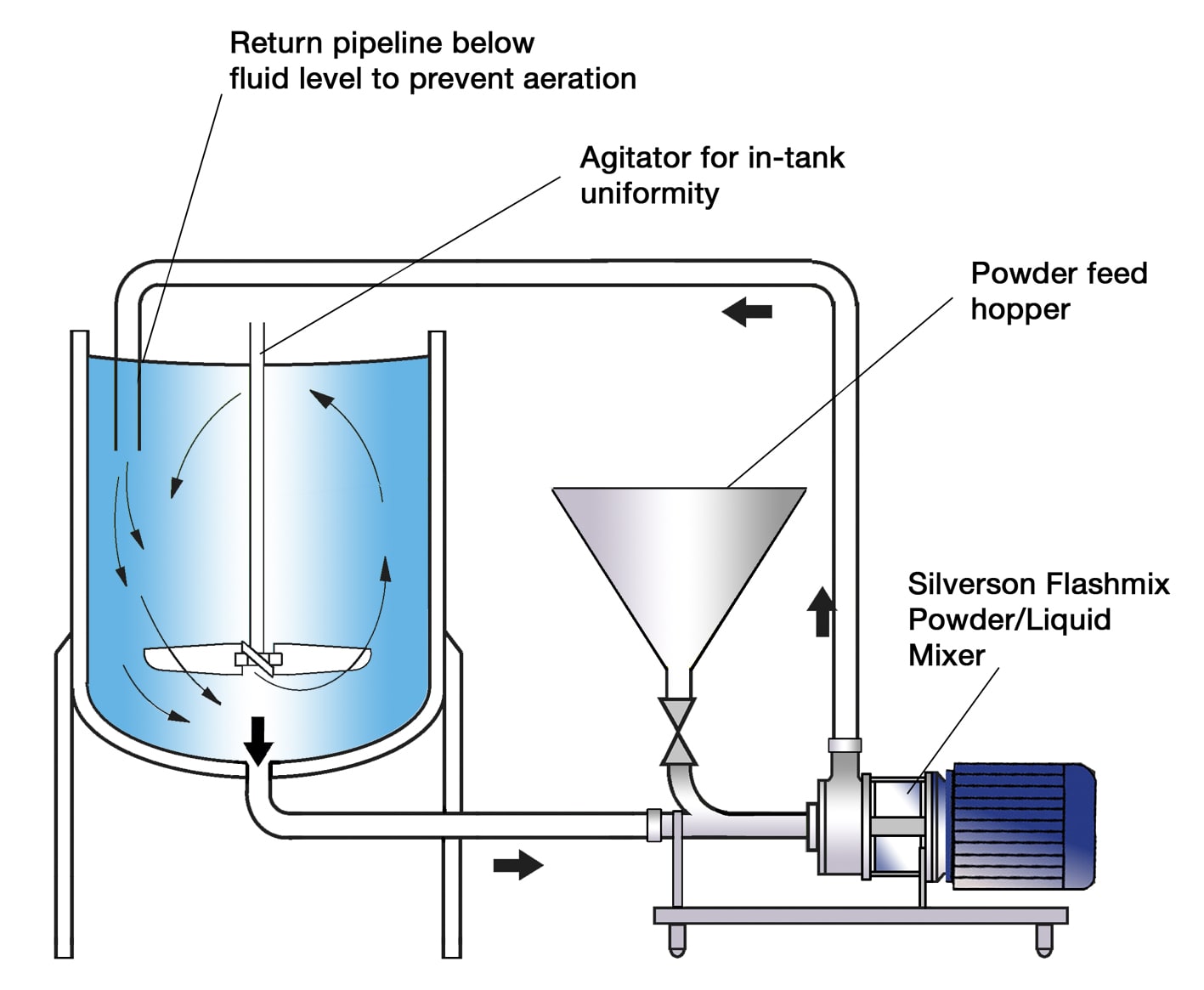

Silverson Flashmix

- Ideal for larger batches

- Capable of rapidly incorporating large volumes of powder

- Minimised aeration

- Minimised cleaning requirements

- Controlled powder addition rate

- Minimum operator input required

- Suitable for high viscosity mixes