Ultramix Mixers

Ultramix Mixers

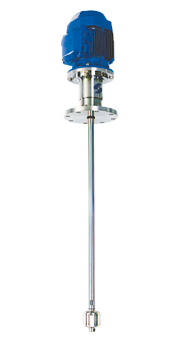

The Silverson Ultramix is designed for applications that are beyond the capabilities of a conventional agitator or stirrer but do not necessarily require the intense high shear of a Silverson rotor/stator mixer.

Ultramix Mixer Advantages:

- Ultra hygienic design - single-shaft, single-piece mixing head.

- The Ultramix series is designed for clean-in-place (CIP) with sterilise-in-place (SIP) as an option.

- Full compliance with 3A TPV (Third Party Verification), USDA and cGMP requirements.

- Excellent in-tank movement is provided by the dynamic mixing head, even when processing high viscosity mixes.

- The powerful vortex can rapidly incorporate large volumes of powders.

- Low maintenance - the single-piece mixing head is of a simple, robust construction with no wearing parts or bushings.

- The design is suitable for applications from aggressive chemical service to the most demanding sanitary standards and requirements.

How It Works

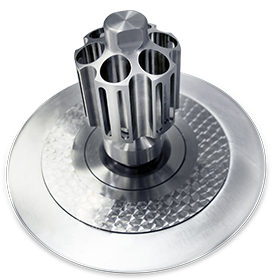

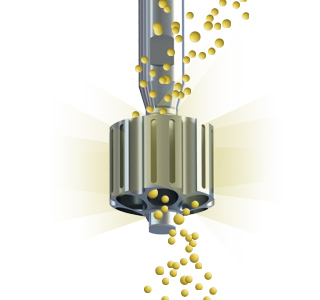

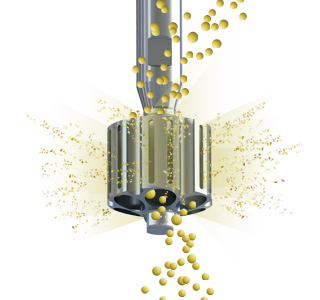

As the mixer rotates at high speed, the grooves on the outside of the dynamic mixing head project the surrounding product outwards with great force, creating an area of low pressure around the trailing edge of each groove.

This draws product from within the mixing head, through the radial slots to the outside, subjecting the material to a shearing action. The grooves in the head drive the product outwards into the body of the mix at high velocity.

As material is drawn out of the slots, fresh material is sucked in through the holes in the top and bottom of the mixing head; this material is then drawn out through the slots and projected back into the mix. The pumping effect of the grooves and the shear action of the radial slots ensures rapid mixing, and develops a vigorous axial flow pattern throughout the vessel.

-

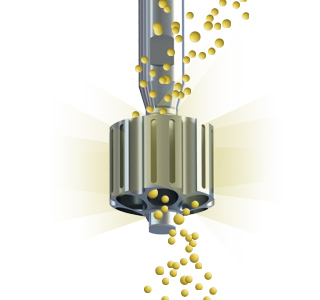

Stage 1

Stage 1

As the mixer rotates at high speed, the grooves on the outside of the dynamic mixing head project the surrounding product outwards with great force, creating an area of low pressure around the trailing edge of each groove.

-

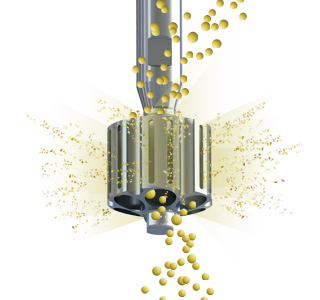

Stage 2

Stage 2

This draws product from within the mixing head, through the radial slots to the outside, subjecting the material to a shearing action. The grooves in the head drive the product outwards into the body of the mix at high velocity.

-

Stage 3

Stage 3

As material is drawn out of the slots, fresh material is sucked in through the holes in the top and bottom of the mixing head; this material is then drawn out through the slots and projected back into the mix. The pumping effect of the grooves and the shear action of the radial slots ensures rapid mixing, and develops a vigorous axial flow pattern throughout the vessel.

Videos

Ultramix – In-Tank Mixer

Ultramix – How It Works

Mixer Options

Technical Information

- Capacity

- 5 - 7000 litres.

- Materials of Construction

- All wetted parts in 316L stainless steel. Special material on request.

- Motor Specifications

- TEFV and ATEX approved Flameproof motors are available as standard. Inverter rated, stainless steel and other motors are available as optional extras.

- Mounting

- Stainless steel flange fitting is available as standard.

- Sealing

- V-ring shaft seal as standard.

- Cleaning

- Clean-In-Place (CIP) design. Simple, easy-to-clean construction.

| Model | kW | RPM | A | B | C | Flange | D | E | F |

|---|---|---|---|---|---|---|---|---|---|

| U1 | 0.75 | 3000 | 47.75 | 559 | 520 | 3" | 191 | 152 | 4 x 19 |

| U2 | 1.5 | 3000 | 57 | 660 | 560 | 4" | 229 | 191 | 8 x 19 |

| U4 | 2.2 | 3000 | 70 | 1041 | 608 | 4" | 229 | 191 | 8 x 19 |

| U6 | 5.5 | 3000 | 82.5 | 1397 | 840 | 6" | 279 | 241 | 8 x 19 |

| U7 | 7.5 | 3000 | 89 | 1397 | 777 | 6" | 279 | 241 | 8 x 22 |

| U9 | 5.5 | 1500 | 114 | 1828 | 777 | 6" | 279 | 241 | 8 x 22 |

| U10 | 15 | 3000 | 114 | 1828 | 1032 | 8" | 343 | 298 | 8 x 22 |

| U11 | 11 | 1500 | 127 | 1828 | 1032 | 8" | 343 | 298 | 8 x 22 |

| U15 | 15 | 1500 | 150 | 1828 | 1146 | 10" | 343 | 298 | 8 x 22 |

The dimensions shown are approximate only and certified diagrams should be used for installation purposes. Silverson reserves the right to change dimensions and specifications without notice.