Silverson Mixer Homogenisers

Silverson Mixer Homogenisers

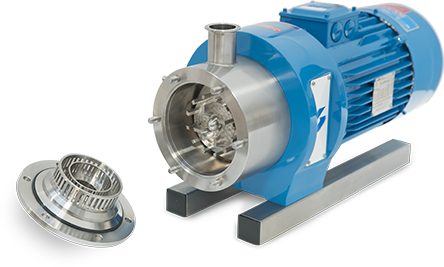

Silverson Mixer Homogenisers are fast and efficient and are capable of producing a fine droplet or particle size, typically in the range of 2 – 5 microns. This degree of homogenisation is suitable for the vast majority of products, such as creams and ointments, lotions, sauces and flavour emulsions.

Silverson offers a range of in-tank and In-Line mixer homogenisers for these applications. The precision-machined Silverson workhead generates exceptionally high shear rates in a three‑stage homogenisation process that rapidly achieves the required uniformity of the product.

Advantages of High Shear Homogenisers Over High‑Pressure Alternatives

- Significantly less capital expenditure

- More energy efficient

- Higher throughput

- Simple to operate, maintain and clean

Enhance High-Pressure Homogenisation Throughput

For the few applications that demand submicron particle or globule sizes, a high-pressure homogeniser may be required. Where this is the case, passing the product through a high shear Silverson Mixer Homogeniser first will dramatically improve throughput, process efficiency and reduce operating costs. This is because a high-pressure homogenizer works better when fed with a premix of uniform and fine globule or particle size, allowing the product to pass through the homogeniser at a much faster rate, normally in a single pass.