Non-Dairy Milk Manufacturing - Plant-Based Milk Alternatives Processing

Dairy-free/vegan alternatives to milk are suspensions of plant-based materials and their extracts in water. There are many different milk alternatives that are made from nuts, seeds, grains and legumes.

Although the final product is used by consumers in similar ways, the manufacturing processes of the various plant-based milks vary according to the raw materials used. This application report will handle the following discreet processes:

- Nut Milks

- Legume Milks

- Seed Milks

- Coconut Milks

- Grain Milks

The Process

Nut Milks:

Nut milks are typically made from almonds, cashews, hazelnuts or macadamia nuts. These drinks can be manufactured from whole nuts, nut pastes or nut powders (or flours). If pastes are utilised, they must be smooth to ensure the correct mouthfeel in the final product. Whole nuts may be roasted to improve flavour, or blanched to aid blending. The final product is typically strained through a fine filter to remove any larger particles. (Note: Cashews and macadamias are the only whole nut or seed that can be used to make milk without straining). Stabilisers and thickening agents such as locust bean gum, gellan gum, acacia gum and carrageenan can be used to improve mouthfeel and extend shelf life. Mineral or vitamin powders may also be added for a fortified product.

Legume Milks:

Soya milk is the most popular legume-based milk. Pea milk is a relatively recent addition to the market and is based on yellow field peas. Soya milk can be manufactured from whole soya beans (through soaking and grinding) or from powders (whole soya flour, soya protein isolate, soya protein concentrate or dried soya powder). Stabilisers and thickening agents such as locust bean gum, gellan gum, acacia gum and carrageenan can be used to improve mouthfeel and extend shelf life. Mineral or vitamin powders may also be added for a fortified product.

Seed Milks:

Non-dairy alternatives to milk can also be based on seeds, most commonly, sunflower or hemp seed. Whole seeds are soaked in water prior to wet grinding. The final product is typically strained through a fine filter to remove any larger particles. Stabilisers and thickening agents such as locust bean gum, gellan gum, acacia gum and carrageenan can be used to improve mouthfeel and extend shelf life. Mineral or vitamin powders may also be added for a fortified product.

Coconut Milks:

Pure coconut milk is typically sold in cans and used in cooking, while coconut milk beverages are typically diluted and sold in cartons. Coconut milk is extracted from the dehusked and deskinned coconut kernel. The flesh is mechanically grated, mixed with water and pressed to obtain the milk, which is filtered to remove large particulates. Although coconut milk contains natural emulsifiers, the product has a tendency to separate during storage with the oil-rich cream floating to the top. Additional stabilisers such as guar gum may be added to prevent this. In areas where fresh coconuts are not abundantly available, recombined coconut milk can be made from concentrated or powdered coconut milk, or from coconut water (the clear liquid found inside the coconut shell). Coconut milk beverages may include other ingredients such as rice or soya. They usually include stabilisers such as pectin or locust bean gum and are often fortified with vitamins and minerals, in order to match the nutritional profile of cow’s milk.

Grain Milks:

The most common grain milks are oat and rice milk. Barley, spelt and buckwheat are also used to manufacture plant-based alternatives to milk.

Oat Milks

Oat milk is manufactured by soaking and blending oats with water. Oil may be added to improve mouthfeel and enhance nutritional value. The final product is typically strained through a fine filter to remove any larger particles. Stabilisers and thickening agents such as locust bean gum, gellan gum, acacia gum and carrageenan can be used to improve mouthfeel and extend shelf life. Mineral or vitamin powders may also be added for a fortified product.

Rice Milks

Industrially, rice milk is typically made by combining rice syrup with water and thickening with rice flour and starch.

The Problem

Nut Milks:

- When manufacturing from paste, solids can settle out in storage, making it difficult to transfer the full quantity from buckets/IBCs. Raw material may be wasted as a result.

- If manufacturing from whole nuts, multiple pieces of equipment are typically required to grind, disperse and reduce the particle size of the nuts in the final product.

- Particle size may not be reduced sufficiently and a large quantity of raw material may be filtered out, resulting in high levels of waste.

- Oil separation may occur in the final product in the event of insufficient mixing.

- Grinding equipment may not be suitable for dispersing thickening and stabilising agents (if used).

- Grinding equipment is not typically hygienic and may be difficult to clean.

Legume Milks:

- Soya flours and protein powders/isolates may have a larger particle size than is acceptable in the final product. Simple dispersion of the powdered raw material may not be sufficient.

- Equipment used to disperse flours and proteins may not be suitable for incorporating additional ingredients such as thickening agents.

- Oil separation may occur in the final product in the event of insufficient mixing.

Seed Milks:

- Particle size may not be reduced sufficiently and a large quantity of raw material may be filtered out, resulting in high levels of waste.

- Oil separation may occur in the final product in the event of insufficient mixing.

- Grinding equipment may not be suitable for dispersing thickening and stabilising agents (if used).

- Grinding equipment is not typically hygienic and may be difficult to clean.

- In the event that thickening agents are not fully dispersed, agglomerates may be filtered out resulting in further waste of raw material.

Coconut Milks:

- Powdered coconut may have a larger particle size than is acceptable in the final product. Simple dispersion of the powdered raw material may not be sufficient.

- If particle size is not reduced to acceptable levels, raw material may be filtered out, resulting in high levels of waste.

- Equipment used to disperse powders may not be suitable for incorporating additional ingredients such as thickening agents.

- Simple agitators may not be capable of forming stable emulsions.

- In the event that thickening agents are not fully dispersed, agglomerates may be filtered out resulting in further waste of raw material.

Grain Milks:

Oat Milks

- The oats should be ground as finely as possible to minimise the amount of waste generated (this residue can be used as animal feed).

- Equipment used for grinding may not be suitable for creating emulsions.

- Grinding equipment may not be capable of dispersing gums and thickeners.

- Grinding equipment is not typically hygienic and may be difficult to clean.

Rice Milks

- A stable emulsion is not easily formed using conventional agitators.

- In some cases, the solution has to be agitated for a long period to ensure that gums are fully hydrated.

The Solution

A Silverson mixer can be used throughout the manufacturing process for a range of non-dairy milks to solve the problems outlined above.

Stage 1

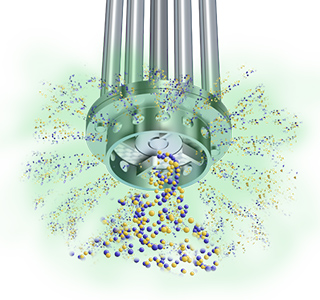

The high-speed rotation of the rotor blades within the precision-machined mixing workhead exerts a powerful suction, drawing liquid and solid materials upwards from the bottom of the vessel and into the centre of the workhead.

Stage 2

Centrifugal force then drives materials towards the periphery of the workhead where they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator.

Stage 3

This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator and circulated into the main body of the mix. The materials expelled from the head are projected radially at high speed towards the sides of the mixing vessel. At the same time, fresh material is continually drawn into the workhead maintaining the mixing cycle.

-

Stage 1

Stage 1

The high-speed rotation of the rotor blades within the precision-machined mixing workhead exerts a powerful suction, drawing liquid and solid materials upwards from the bottom of the vessel and into the centre of the workhead.

-

Stage 2

Stage 2

Centrifugal force then drives materials towards the periphery of the workhead where they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator.

-

Stage 3

Stage 3

This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator and circulated into the main body of the mix. The materials expelled from the head are projected radially at high speed towards the sides of the mixing vessel. At the same time, fresh material is continually drawn into the workhead maintaining the mixing cycle.

The Advantages

- Interchangeable workheads ensure that full dispersion of all ingredients, including thickeners and stabilisers is possible with Silverson mixers, minimising waste.

- The Silverson In-Line mixer can be run at higher speeds to achieve maximum particle size reduction.

- The Ultramix is also suitable for dispersing stabilising agents such as gums and thickeners.

- With the option of interchangeable workheads, the Silverson mixer future proofs the production process. Raw materials can be changed and blends of different plant-based ingredients can be introduced. Dairy/non-dairy blends can also easily be produced with a Silverson mixer.

Solutions range from the high speed Silverson Ultramix, to high shear Batch and In-Line mixers. The batch size, raw material, type of final product and formulation dictate which machine is most suitable.

High Shear Batch Mixers

- Suitable for powder/liquid mixing including flours, starches, gums and thickeners

- Also used for blending liquids of varying viscosities e.g., syrups, pastes and concentrates into water

- Suitable for disintegrating nuts, seeds and other solids (depending on starting particle size) and can be used in conjunction with an In-Line mixer

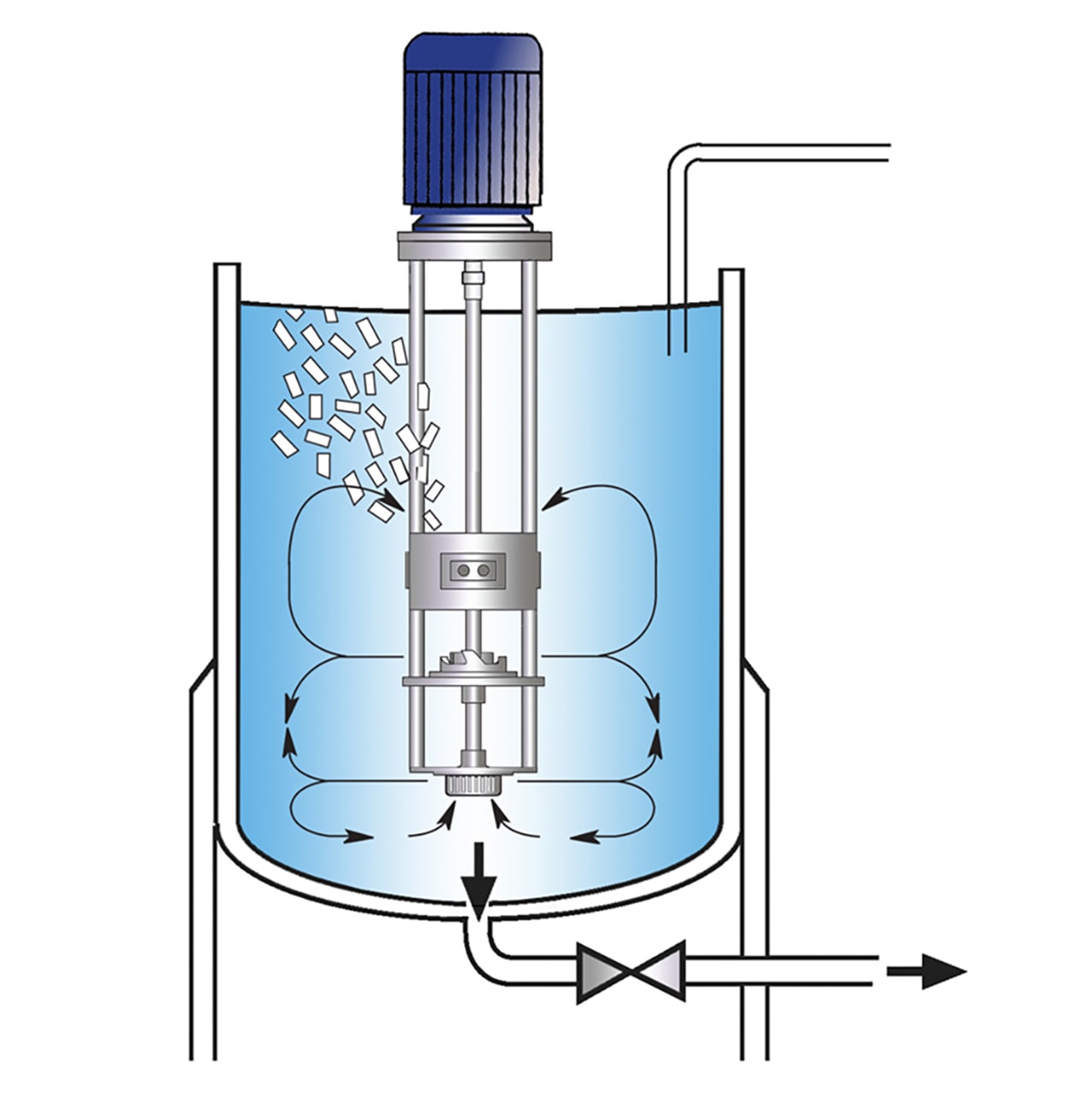

- A Silverson Duplex (Illustrated) can be used for disintegration of larger nuts, seeds and other solids, again, often in conjunction with an In-Line mixer

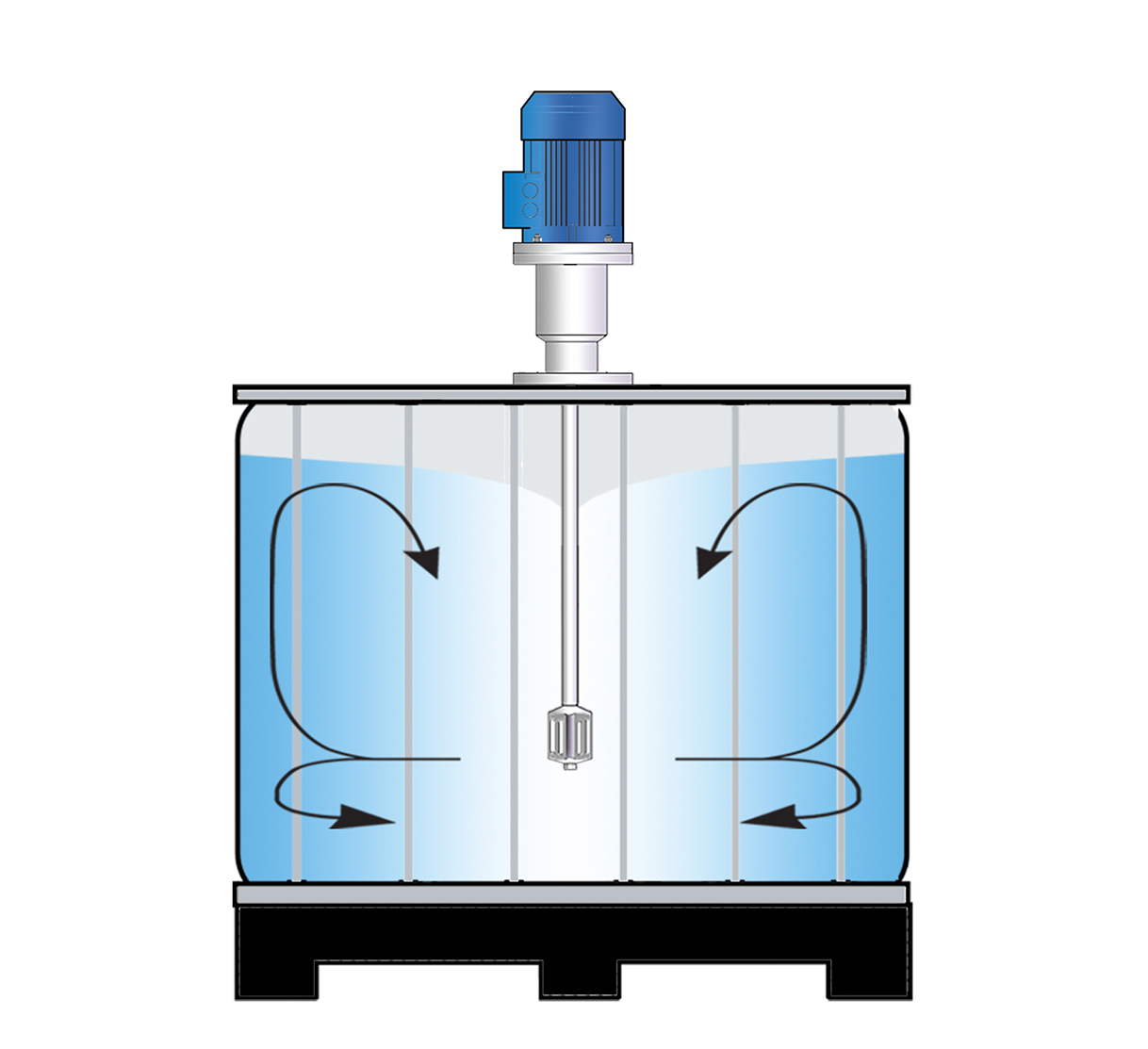

Silverson Ultramix

- Suitable for blending liquids of varying viscosities

- Dispersion of gums and thickeners

- Ideal for resuspending solids in pastes when supplied in IBCs due to the small diameter mixing head

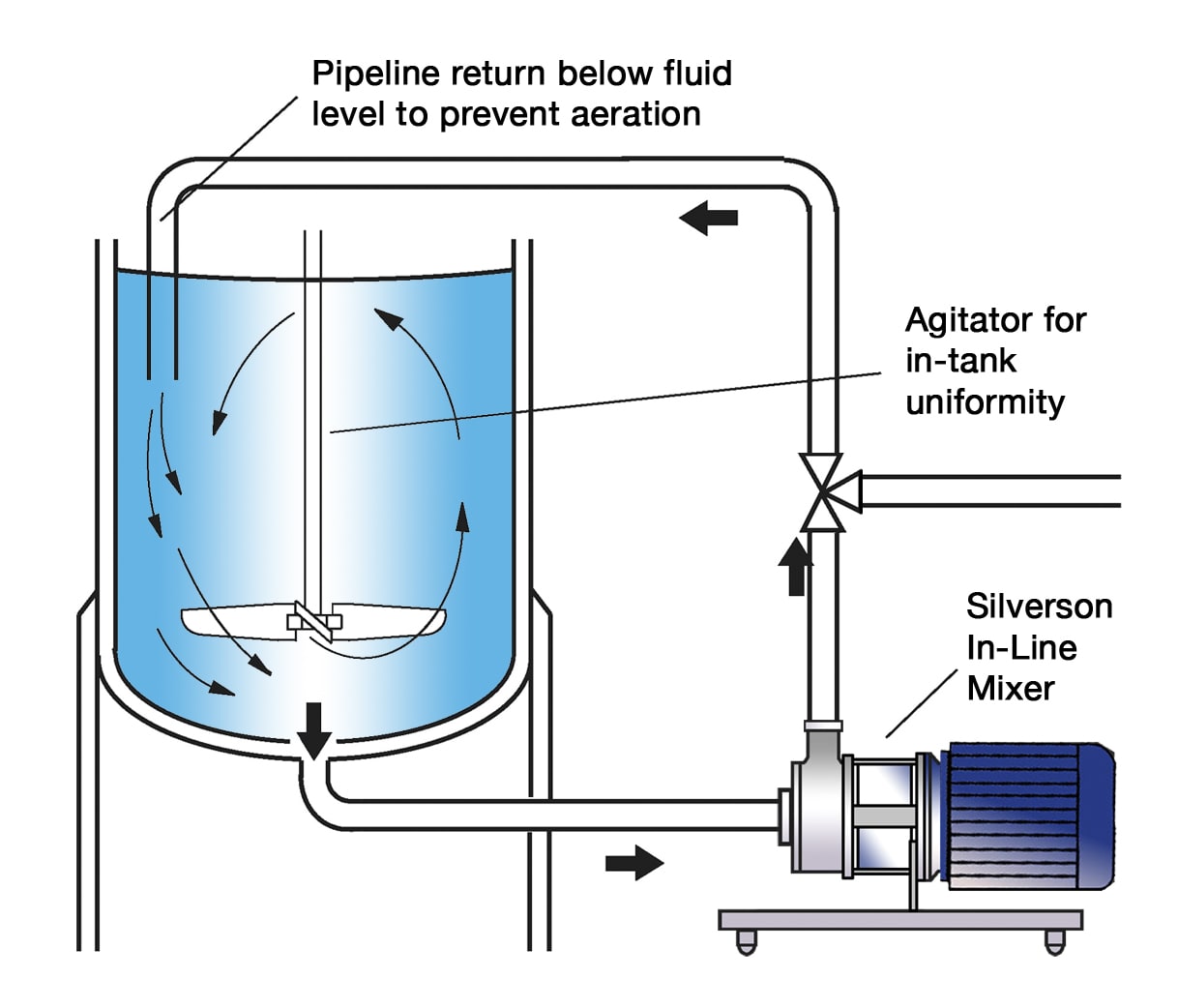

High Shear In-Line Mixers

- Ideal for larger batches

- Suitable for blending powders and pastes, may be used with an agitator in larger tanks

- Used in conjunction with Batch Mixers, Duplex Disintegrators and Bottom Entry mixers where whole nuts, seeds or oats are used; the In-tank mixer provides the initial particle size reduction and the In-Line mixer further refines the product to obtain the desired finished texture

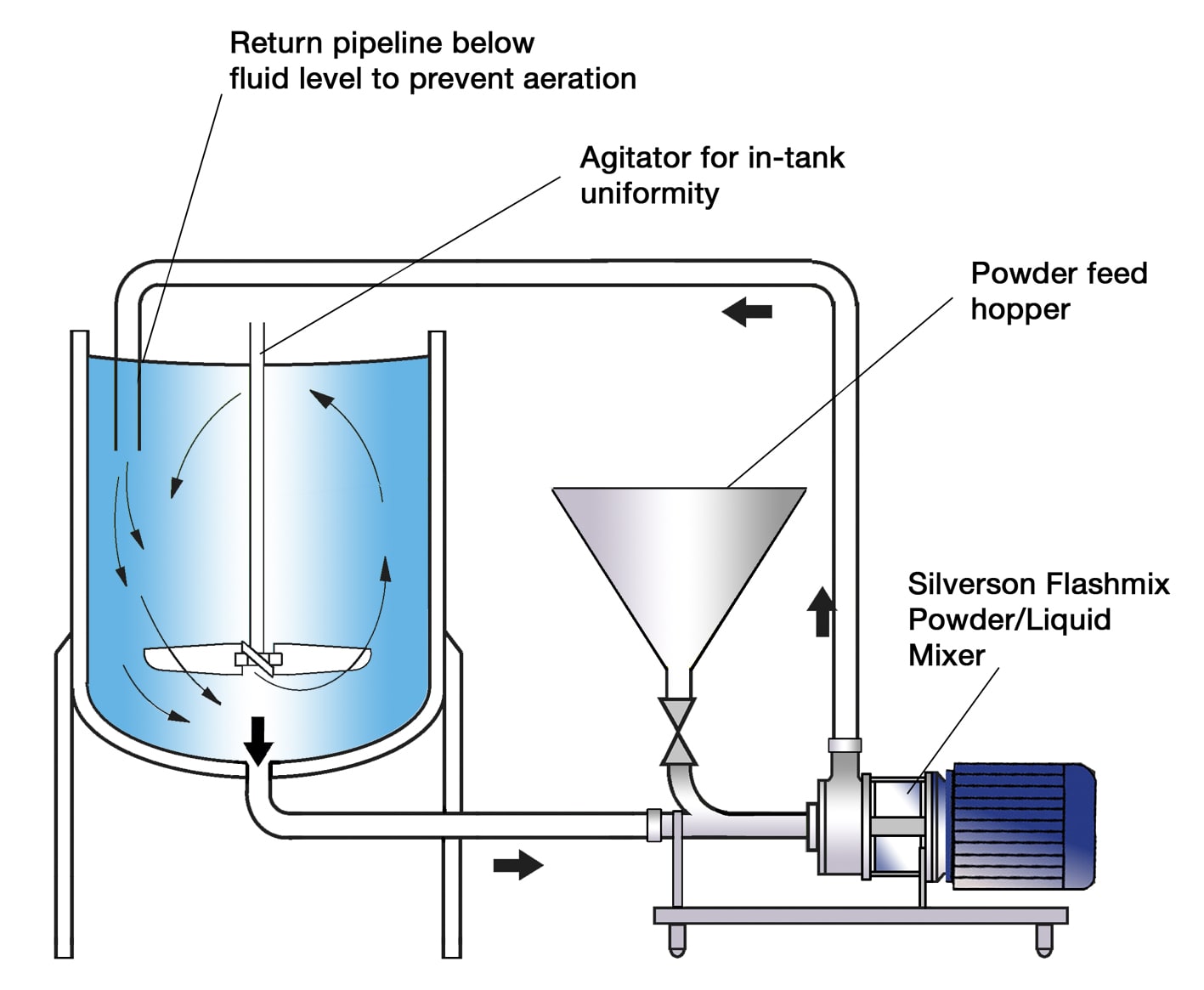

Silverson Flashmix

- Designed for bulk powder dispersion

- Ideal for manufacturing products based on flours and other powders

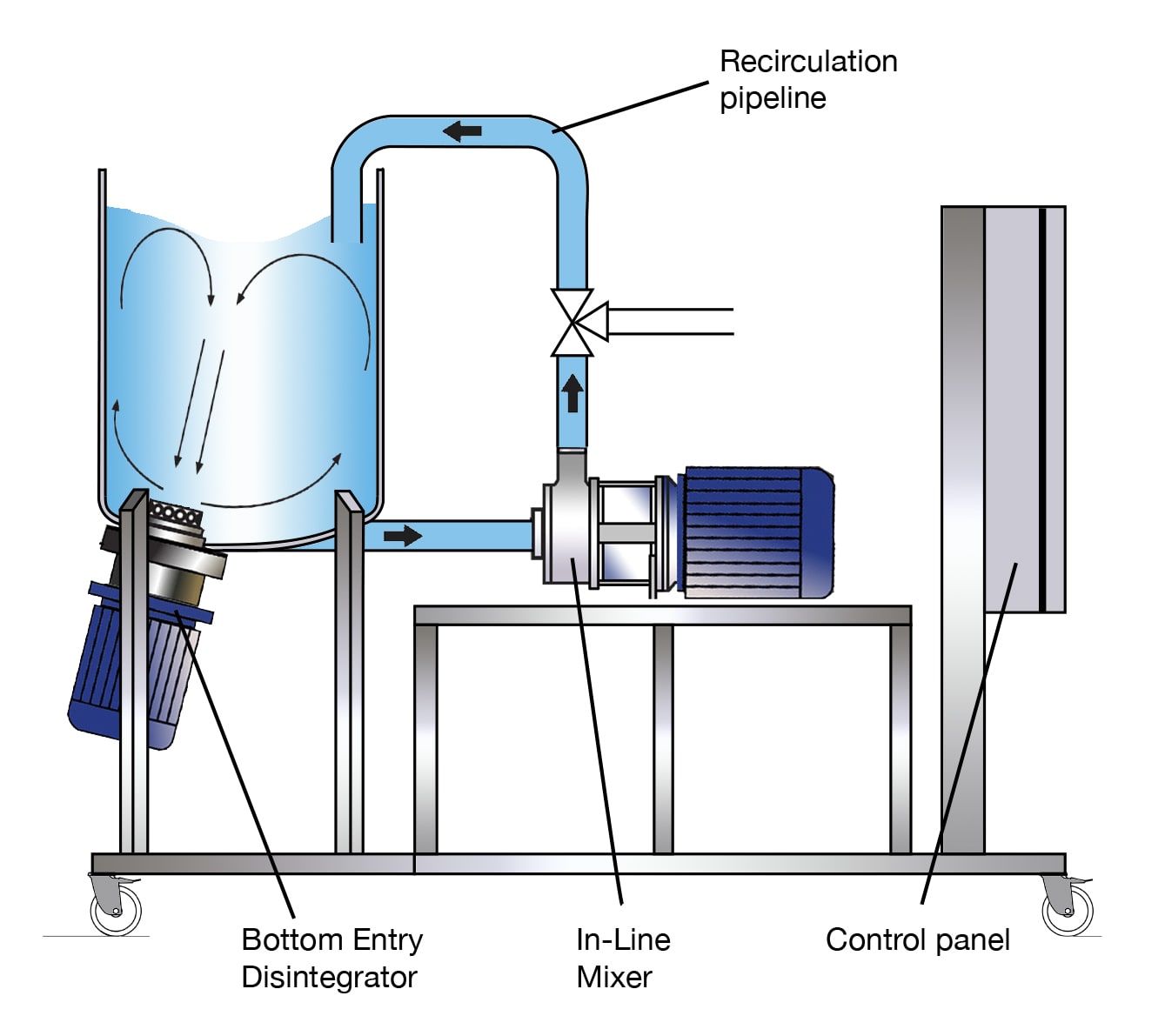

Silverson Pilot Disintegrator Plant

- Combining a Bottom Entry disintegrator and an In-Line mixer/homogeniser

- Ideal for production process where whole nuts, seeds or oats are being processed. The Bottom Entry mixer provides the initial particle size reduction, dispersion or blending and the In-Line mixer further refines the product to obtain the desired finished texture

- Can be customised to suit individual process requirements