Manufacture of Cloud Emulsions for Soft Drinks

Clouding agents are used in soft drink manufacture to give a more natural appearance to products with a low juice content; they can also mask sedimentation and “ringing” - where colouring/flavouring oils rise to the surface of the container during storage. Clouding agents are normally supplied as emulsions similar to flavour emulsions. A typical formulation would contain the following:

- Clouding Agent: The clouding effect is obtained from fractions of oils with a neutral a flavour as possible. Citrus oils are the most widely used; vegetable oil is used, but less common due to poor resistance to oxidation.

- Stabilisers: The emulsion is stabilised with gum, typically gum arabic.

- Weighting or Densifying Agents: Added to prevent “ringing.” Originally Brominated Vegetable Oil (BVO) was common, but its use is now restricted. Typically resin gums such as damar gum are used.

The Process

Typically cloud emulsions are oil-in-water emulsions. A typical manufacturing process would be as follows:

- The gum (stabiliser) and any other additives would be dispersed into water to form the continuous phase of the emulsion.

- The citrus oil or other clouding agent is premixed with the weighting agent, added to the vessel and mixed to form a pre-emulsion.

- The pre-emulsion is then passed through a high pressure homogeniser to obtain the required globule size.

The Problem

Preparing a pre-emulsion with conventional agitators can lead to a number of problems:

- Powders must be added at controlled rate to reduce agglomeration of particles.

- Conventional systems do not produce sufficient shear to break agglomerates down.

- Agitation of the solution and dispersion of powders becomes more difficult as the viscosity increases.

- Long processing times are required to complete dispersion and achieve a satisfactory consistency.

- A uniform pre-emulsion is required by the high pressure homogeniser. This is not possible using conventional agitators.

- Obtaining full yield of stabilisers is difficult using traditional methods.

- Partially hydrated material can build up on the shaft of the mixer and on the vessel wall.

- The net result of conventional mixing is the product having to be passed several times through the high pressure homogeniser to obtain desired globule size.

The Solution

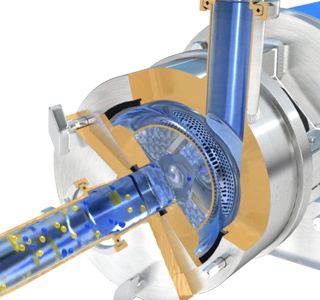

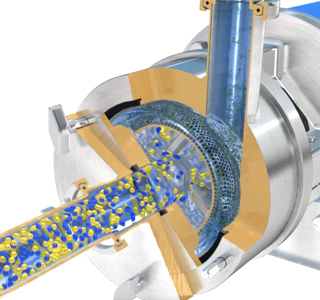

A Silverson High Shear mixer can overcome these problems. The high shear action of the rotor/stator workhead hydrates and disperses the powdered ingredients and produces a finely dispersed pre-emulsion as follows:

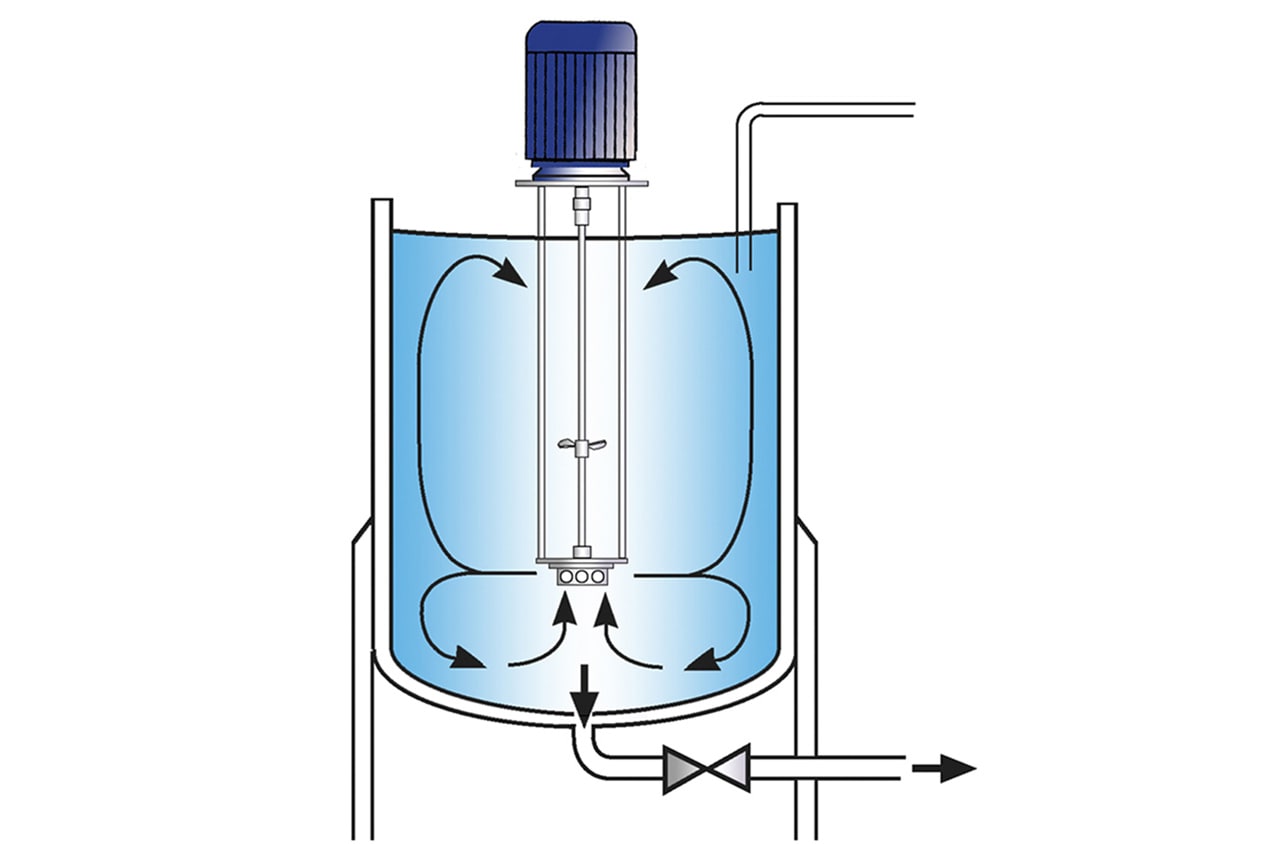

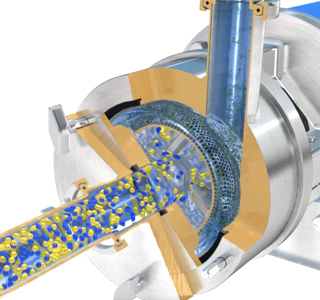

Stage 1

The vessel is charged with liquid and the mixer is started. The powdered ingredients are then added. The high speed rotation of the rotor blades creates a powerful suction which draws the liquid and powdered ingredients into the workhead.

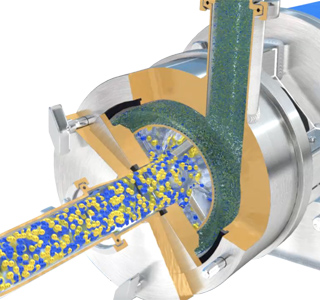

Stage 2

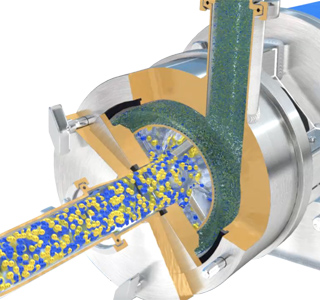

Centrifugal force drives the materials to the periphery of the workhead where they are sheared in the gap between the rotor and the stator. The product is forced out of the stator and projected radially back into the body of the mix as fresh ingredients are drawn into the workhead.

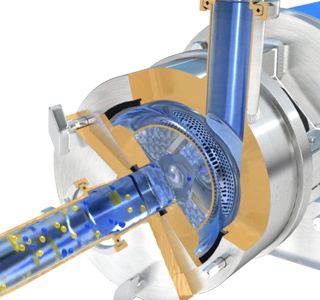

Stage 3

The oil phase ingredients are added to the vessel and an emulsion is rapidly formed. In a short mixing cycle all the material passes through the workhead, progressively reducing particle/globule size to produce a stable, fine pre-emulsion.

-

Stage 1

Stage 1

The vessel is charged with liquid and the mixer is started. The powdered ingredients are then added. The high speed rotation of the rotor blades creates a powerful suction which draws the liquid and powdered ingredients into the workhead.

-

Stage 2

Stage 2

Centrifugal force drives the materials to the periphery of the workhead where they are sheared in the gap between the rotor and the stator. The product is forced out of the stator and projected radially back into the body of the mix as fresh ingredients are drawn into the workhead.

-

Stage 3

Stage 3

The oil phase ingredients are added to the vessel and an emulsion is rapidly formed. In a short mixing cycle all the material passes through the workhead, progressively reducing particle/globule size to produce a stable, fine pre-emulsion.

The Advantages

- After processing with a Silverson mixer, a single pass through a high pressure homogeniser is normally sufficient to achieve the required globule size in the end product.

- The high pressure homogeniser can be eliminated in some cases.

- Typically a globule size of down to 1µm is achievable.

- Ability to start up or stop process quickly for processing of ingredients on demand.

- Agglomerate-free mix.

- Consistent product quality and repeatability.

- Stable pre-emulsion.

- Maximised yield of raw materials as thickening agents are fully hydrated and other ingredients fully dispersed.

- Dramatic reduction in mixing times.

- Improved vessel hygiene.

There are several products in the Silverson range suitable for this application, the selection of which is dictated by individual process requirements including batch size:

High Shear Batch Mixers

- Suitable for batch sizes up to 1000 litres

- Many units can be used on mobile floor stands

- Small units available for R&D and pilot production

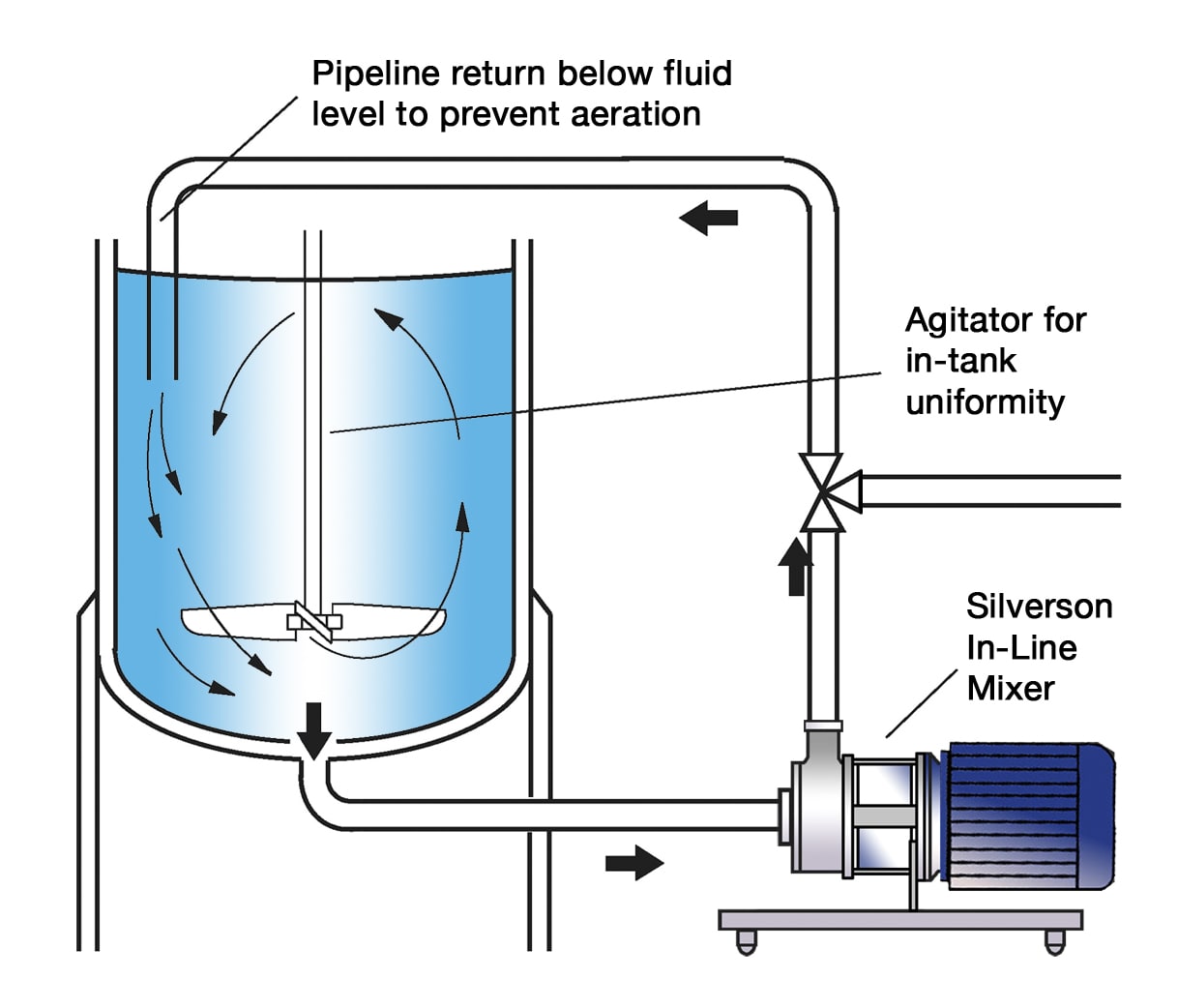

High Shear In-Line Mixers

- Ideal for larger batches

- Aeration free

- Easily retrofitted to an existing plant

- Self-pumping

- Can be used to discharge vessel

- Ultra Hygienic models available

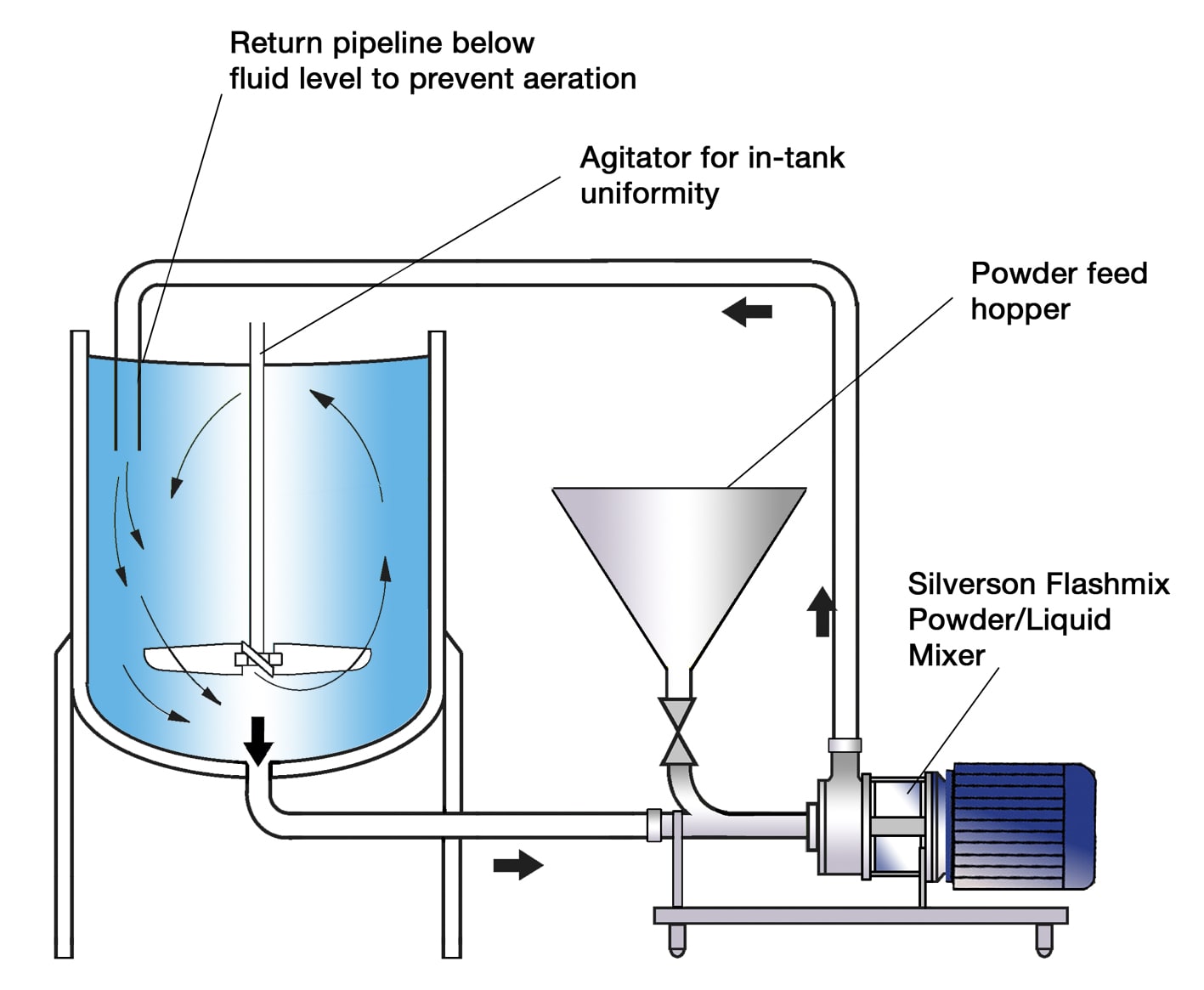

Silverson Flashmix

- Ideal for larger batches

- Capable of incorporating large volumes of powders

- Minimised aeration

- Minimised cleaning requirements

- Suitable for higher viscosity mixes

- Suitable for operation at higher temperatures

- Minimum operator input required