Manufacture of Baby Milk and Infant Formula

Baby milk or infant formula is primarily used as a substitute for human milk. Other uses include “Follow-up” products as a dietary supplement for older infants and special formulations for specific nutritional needs or to overcome allergies e.g. soya-based milks for lactose intolerant infants. The finished product is either supplied as a spray dried powder which is reconstituted as required, or in liquid form packed in “ready to use” sterile feeding bottles. Typically added ingredients include Milk proteins, Lactose, Soya protein, Maltodextrin and various vitamins and minerals.

The selection of raw materials, formulation, manufacturing and storage of baby milks is one of the most stringently regulated in the food industry.

The Process

A typical mix would be prepared in the following manner:

- The base liquid which may be either milk or water is weighed/metered into the process vessel. The liquid may be heated to aid dissolving/hydration of powdered ingredients.

- Powdered ingredients - milk proteins, etc. are added to the liquid and mixed until dispersed. Some heat-sensitive ingredients (e.g. vitamins) may be added at a later stage.

- The premix is usually homogenised by passing through a high pressure homogeniser.

- The product is heat sterilised/pasteurised.

- The product is spray dried before packing.

The Problem

Preparation of the premix is subject to a number of problems when using agitators and conventional powder/liquid blending systems:

- The powders are very cohesive and must be added at a controlled rate to reduce lump formation.

- Conventional systems do not produce sufficient shear to break down agglomerates.

- Long processing times are required to complete dispersion and achieve a lump-free premix for homogenisation.

- The vigorous agitation required to disperse the powder can lead to foaming.

- The process must be carried out in the most hygienic manner as possible. Problems can arise with conventional systems as they tend to allow a build-up of partially hydrated powder on vessel walls and mixer shafts, etc. raising potential hygiene issues.

- Premixing the ingredients at raised temperatures increases the risk of bacterial contamination.

The Solution

A Silverson High Shear mixer can produce an agglomerate-free premix in a fraction of the time taken by conventional methods. The high concentration of solids made possible by high shear mixing can eliminate the evaporation stage.

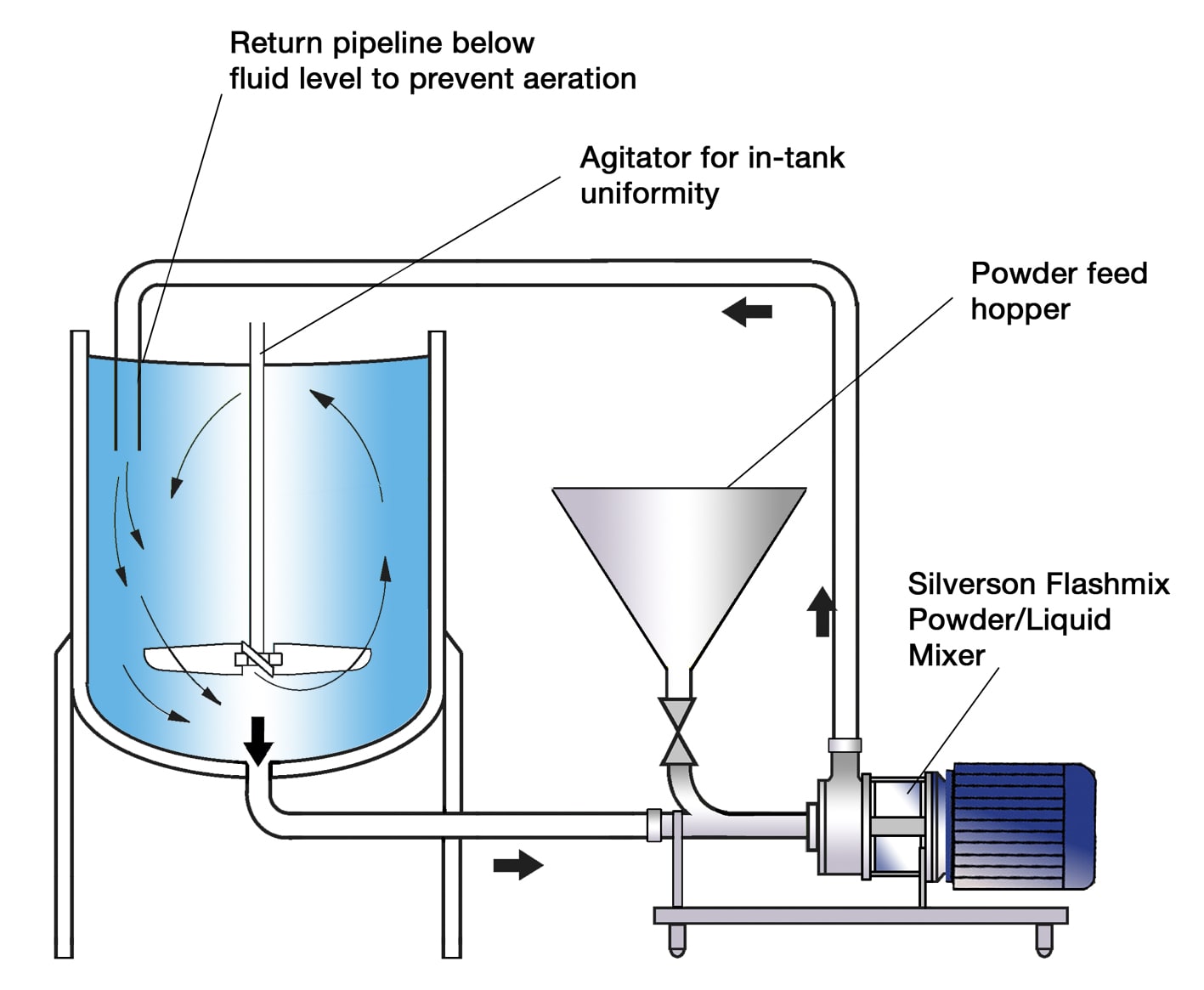

For the large volumes typical of most production facilities, the Silverson Flashmix is most suitable (see below).

The self-pumping Flashmix draws water from the vessel into the high shear rotor/stator workhead then recirculates it back into the top of the vessel. The powder is fed into the specially designed hopper. Once the water is recirculating the powder feed can be opened. The powder is drawn into the liquid stream and passes immediately to the inlet of the In-Line mixer. The liquid and solids are subjected to intense high shear in the workhead of the In-Line mixer before being pumped back into the vessel. A short recirculation period completes the hydration process.

The Advantages

The Silverson Flashmix offers many advantages over conventional systems:

- Ideal for larger batches or repeated smaller batches

- Designed for bulk powder dispersion

- Capable of incorporating large volumes of powders

- Minimised aeration

- Minimised cleaning requirements

- Suitable for higher viscosity mixes

- Suitable for operation at higher temperatures

- Minimum operator input required

- Ultra Hygienic models available

Other models may be used depending on certain factors.

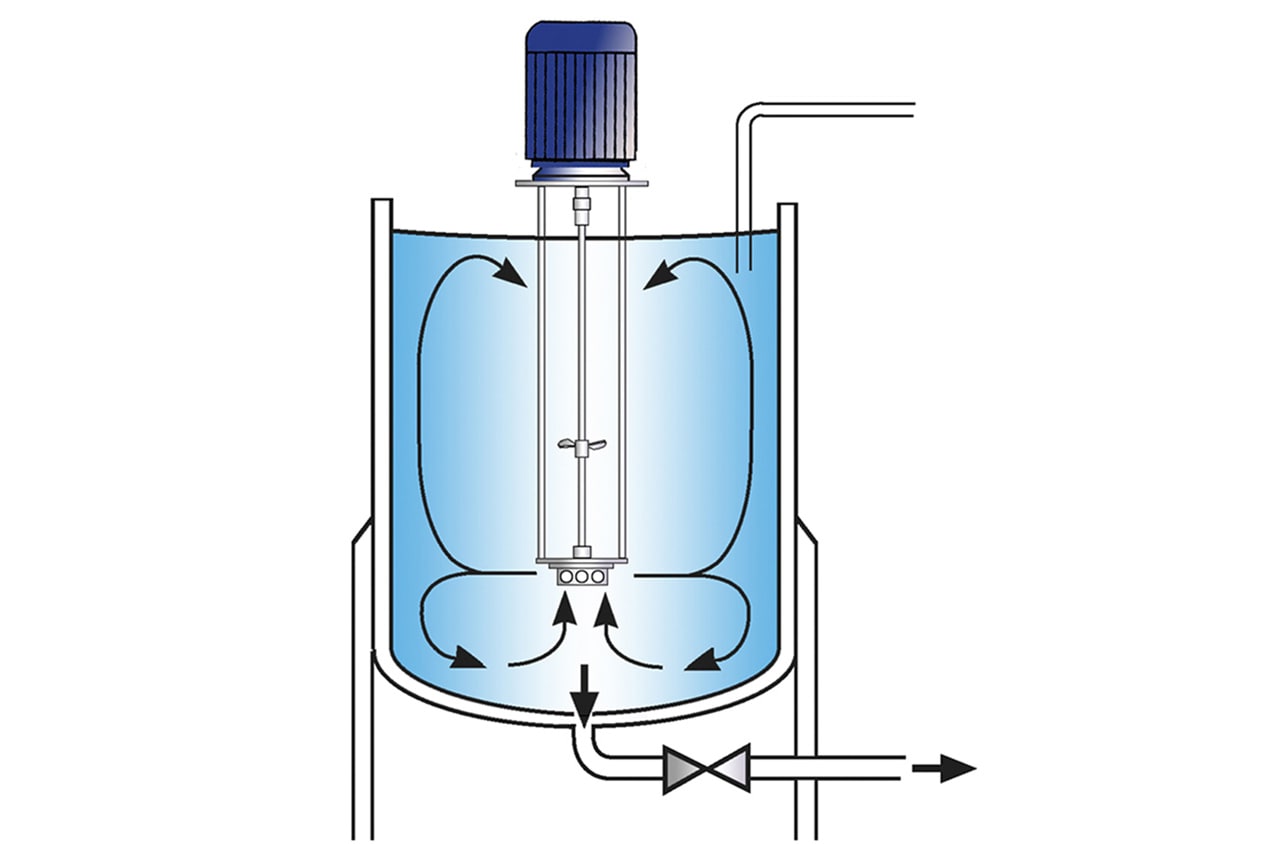

High Shear Batch Mixers

- Suitable for R&D and pilot scale

- Can be used on mobile floor stands

- Can easily be moved from vessel to vessel

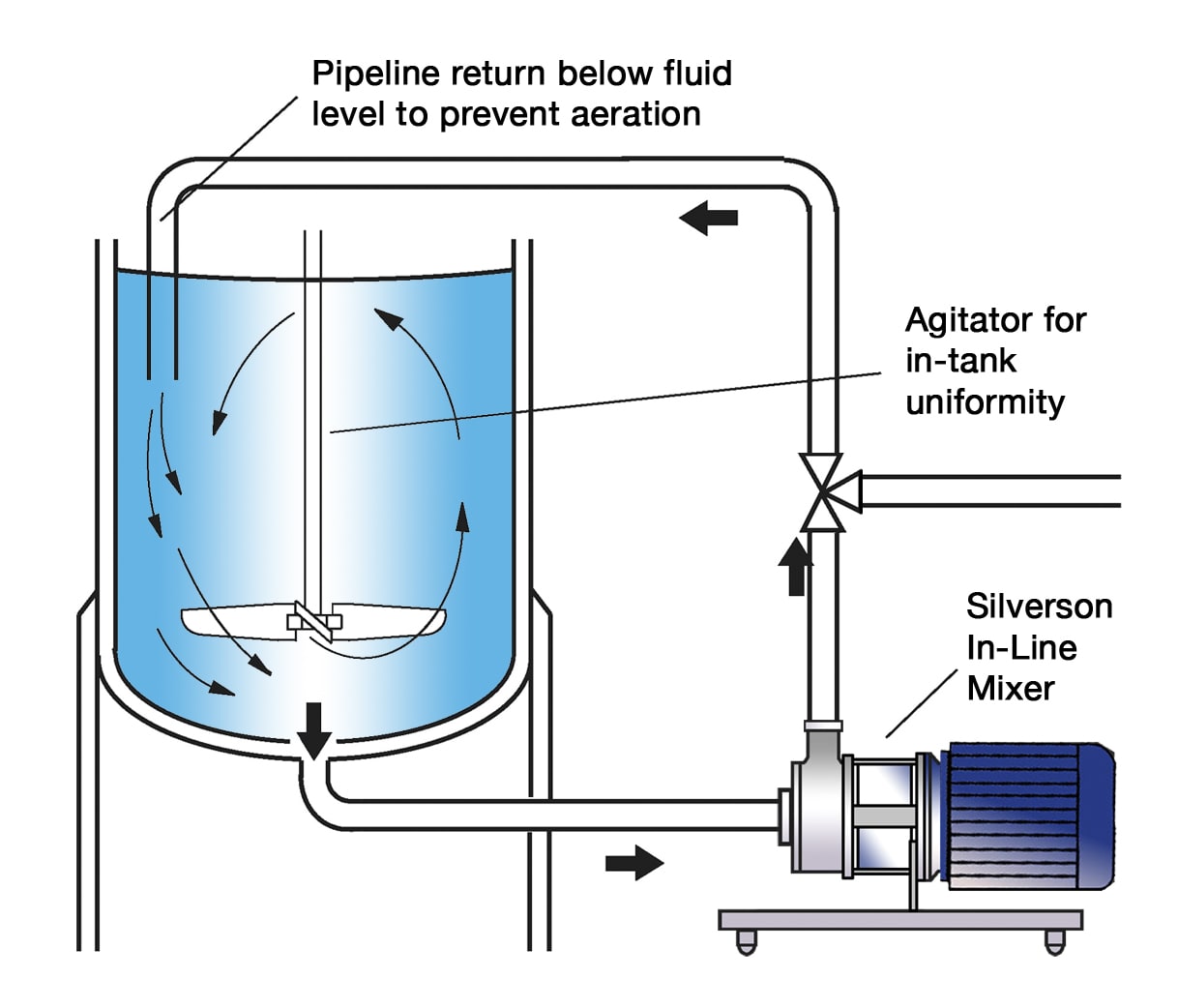

High Shear In-Line Mixers

- Easily retrofitted to existing plant

- Should be used in conjunction with an efficient in-tank agitator to wet out powder

- Aeration free

- Self-pumping

- Can be used to discharge vessel

- Models for CIP and SIP available

- Ultra Hygienic models available

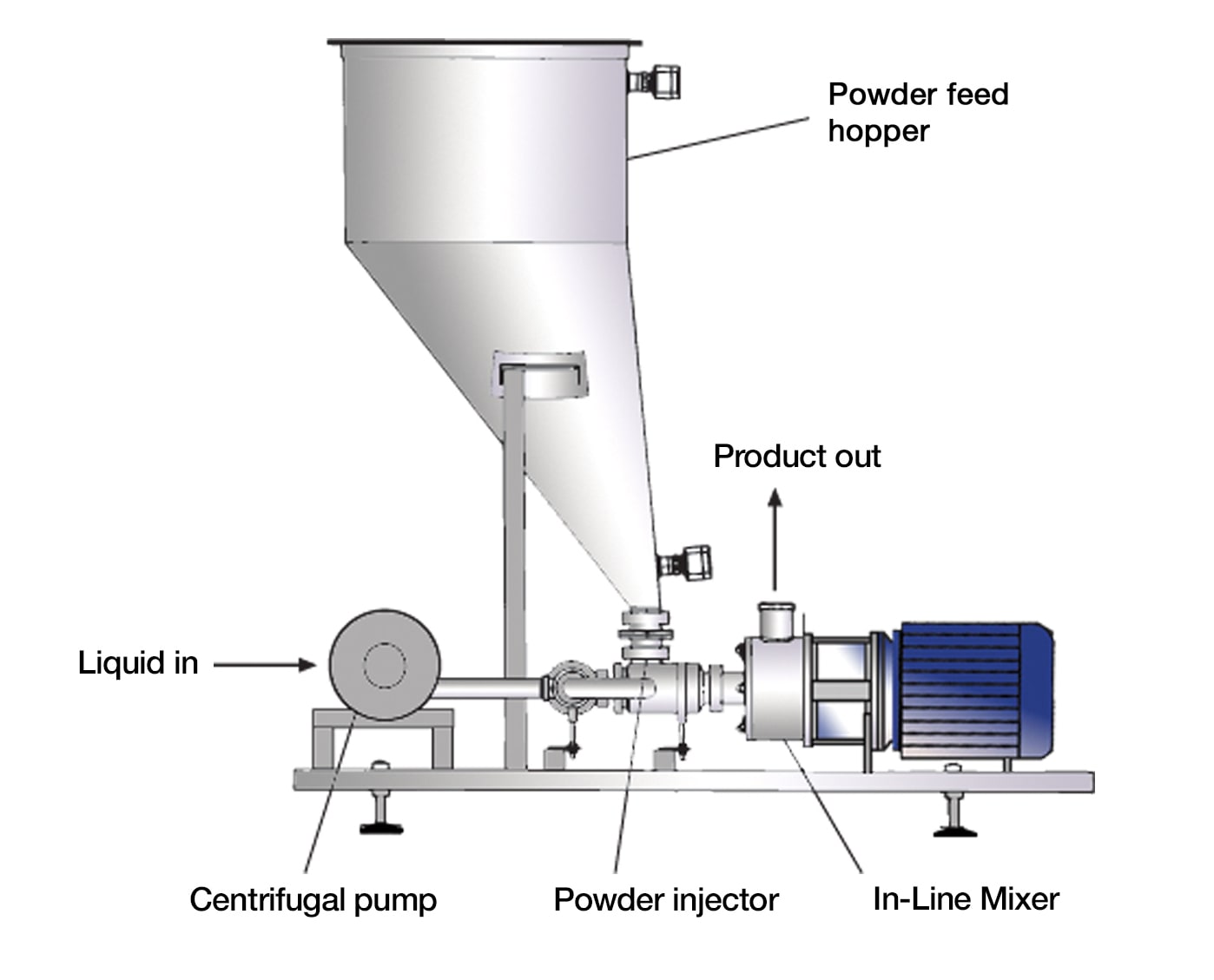

Silverson Flashblend

- Up to 48% solids can be dispersed into water

- The Flashblend is designed to work efficiently at ambient temperatures, reducing the risk of bacterial contamination and damage to nutrients such as vitamins and minerals

- Premixing of powdered ingredients is not necessary

- Ideal for large batches

- Capable of incorporating large volumes of powders

- Agglomerate-free mix

- Rapid mixing times

- Controlled powder addition rate

- Designed for CIP (Cleaning-In-Place) and can be supplied for SIP (Sterilise-In-Place) operation

- Improved process hygiene

- Optional hopper flow aids available for difficult powders

- Minimised aeration

- Minimum operator input required